Home ›Products › Eps Panels Machinery › Foam Recycling Machine

|

Model No. & Type

|

Power(kw)

|

Capacity(kg/h)

|

Center(mm)

|

Input(mm)

|

Particle(mm)

|

|

175 integrated

|

11

|

75-100

|

580

|

220

|

3-5

|

|

220 integrated

|

18.5

|

175-200

|

620

|

280

|

4-6

|

|

220 divided

|

15

|

150-200

|

620

|

300

|

4-6

|

|

320 divided

|

18.5-22

|

225-250

|

780

|

330

|

4-6

|

|

350 divided

|

22-30

|

300-350

|

820

|

350

|

4-6

|

Introduction

Eps granulator line is also called foam recycling machine, it includes eps shredder, pipe, silo, granulator main machine, water channel, cutter etc. The line is used for making recycled eps foam, expandable polyethylene etc into ps particles which can be used in making extruded polystyrene products.

It is automatic ,dual screw type, with temperature control. Mentioning of the layout of upper and down screw,we have integrated and separate types.

1) Screw materials are made by high carbon chromium bearing steel. Its anti-friction and anti-rust are good performance. The actual capacity is by the conditions of the feeding on the screw and the output of mold head,our machine is designed with good screw type which is by our years of experience.

2) Feeding inlet is designed considering of the different density of the materials. Customer can control the feeding speed.

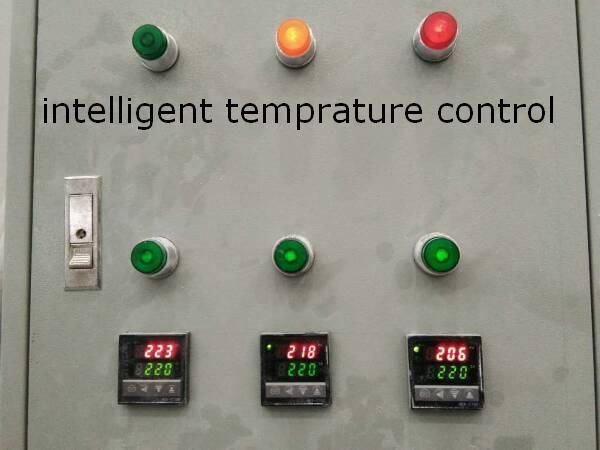

3) Temprature control box enable customers know the work conditions such as the temperature of the screw,customers can adjust it depending on the noodles color. it avoid the cases of overheat or melting failure.It is also good for make more transparent particles.

4) Wire mesh auto exchange device. The device on the mold head make the machine work without stop.

5) Protection on shelter makes workers safe during work.Eps the shelter on motor and the heater. Also,it makes the machine good looking.

Application materials: used eps foam blocks, expandable polyethylene ,such as various package foam,lunch box, foam scraps.

Procedure: crushing ---> plastify --->noodles ---> cooling ---> cutting

Advice for choosing your capacity

1) Economical machine is suitable for beginners or small capacity users.

2) Model 220 with single/double reducers is suitable for 10 ton/monthly capacity.It is with temperature control box and wire mesh auto exchange device, the output particles are with good quality.

3) Model 320,350 are suitable for big capacity user who knows the filed, it is with small power and big capacity.

Warranty clause

We give one year warranty service. Parts are available free within one year in case of quality problem

Prev: foam crusher

Related Items

Product Category

Hot Items

Live Help

0086 13833131292

0086 13833131292 0086 311 86558425

0086 311 86558425